Mecal News

5 Tips for Better Crimps

Here are 5 tips to make sure you're achieving the best crimps possible:

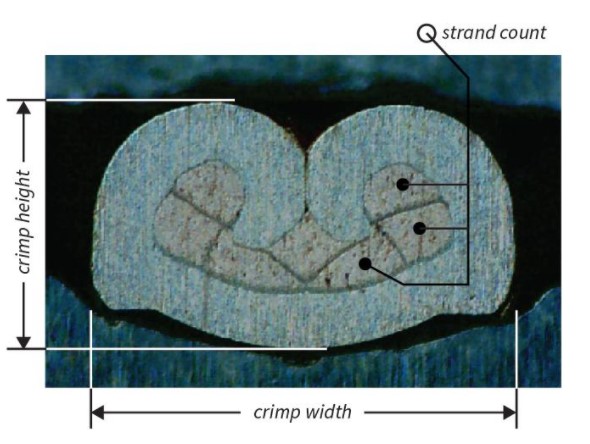

1) Understand what makes a good crimp and what makes a bad crimp. We have a quality crimping guide available for download on our website here 2) Make sure your materials are well prepared. This includes ensuring that the reel holder is adjusted to the correct height, the terminals are not bent or damaged, and the applicator is free of debris and well lubricated.

3) Inspect the regulating head and the data plate to make sure it is at the correct setting for the specified wire size.

4) Before production, the ram, roller pin, cam, as well as inside of the cast body should be lightly coated with white lithium grease. The main ram and down inside the cast body are the most important areas to grease and maintain a light coat of grease throughout production. You can remove the ram from the body but be sure to leave the red safety collar, provided with each applicator, on the ram when re-inserting it into the body.

5) Inspect your applicator if there were any incidents (misfeed, double feeds, or terminals stuck to the crimp tools). Remove the applicator from the press, and the ram from the applicator body inspect and evaluate to ensure no damage has occurred to crimp tools. Replace any necessary damaged parts, re-align the tooling if necessary utilizing plastic paper to ensure crimp plates and anvils do not come in contact with each other.

2) Make sure your materials are well prepared. This includes ensuring that the reel holder is adjusted to the correct height, the terminals are not bent or damaged, and the applicator is free of debris and well lubricated.

3) Inspect the regulating head and the data plate to make sure it is at the correct setting for the specified wire size.

4) Before production, the ram, roller pin, cam, as well as inside of the cast body should be lightly coated with white lithium grease. The main ram and down inside the cast body are the most important areas to grease and maintain a light coat of grease throughout production. You can remove the ram from the body but be sure to leave the red safety collar, provided with each applicator, on the ram when re-inserting it into the body.

5) Inspect your applicator if there were any incidents (misfeed, double feeds, or terminals stuck to the crimp tools). Remove the applicator from the press, and the ram from the applicator body inspect and evaluate to ensure no damage has occurred to crimp tools. Replace any necessary damaged parts, re-align the tooling if necessary utilizing plastic paper to ensure crimp plates and anvils do not come in contact with each other. MECAL BY STARN OFFERS

Presses ranging from 1.5 to 20 ton capabilities.

Mecal By Starn Sales

Mecal By Starn started as a partnership between Mecal and Starn Tool in order to supply North American Wire Harness Industry with world-class applicators, presses and spare parts from Mecal. Mecal was established in 1976 with the aim of supplying the wire harness industry with the best crimping equipment available. While Starn Tool, a well-respected precision machining company since 1945, has supported the wire harness industry since the 1960’s.

Today, Mecal by Starn is known for its customer service excellence across its expansive product line, as well as innovation and capability in custom-designed solutions to meet customer needs and help solve complex project challenges.

Mecal News

Meet Mauricio Valdebenito

Perishable Tooling & Reverse Engineering Solutions

A Better Option for your Production

WANT TO GET STARTED?

Talk to One of Our Experts