Mecal News

Wire Harness Crimping Quality

Here are 4 common quality issues that you should monitor

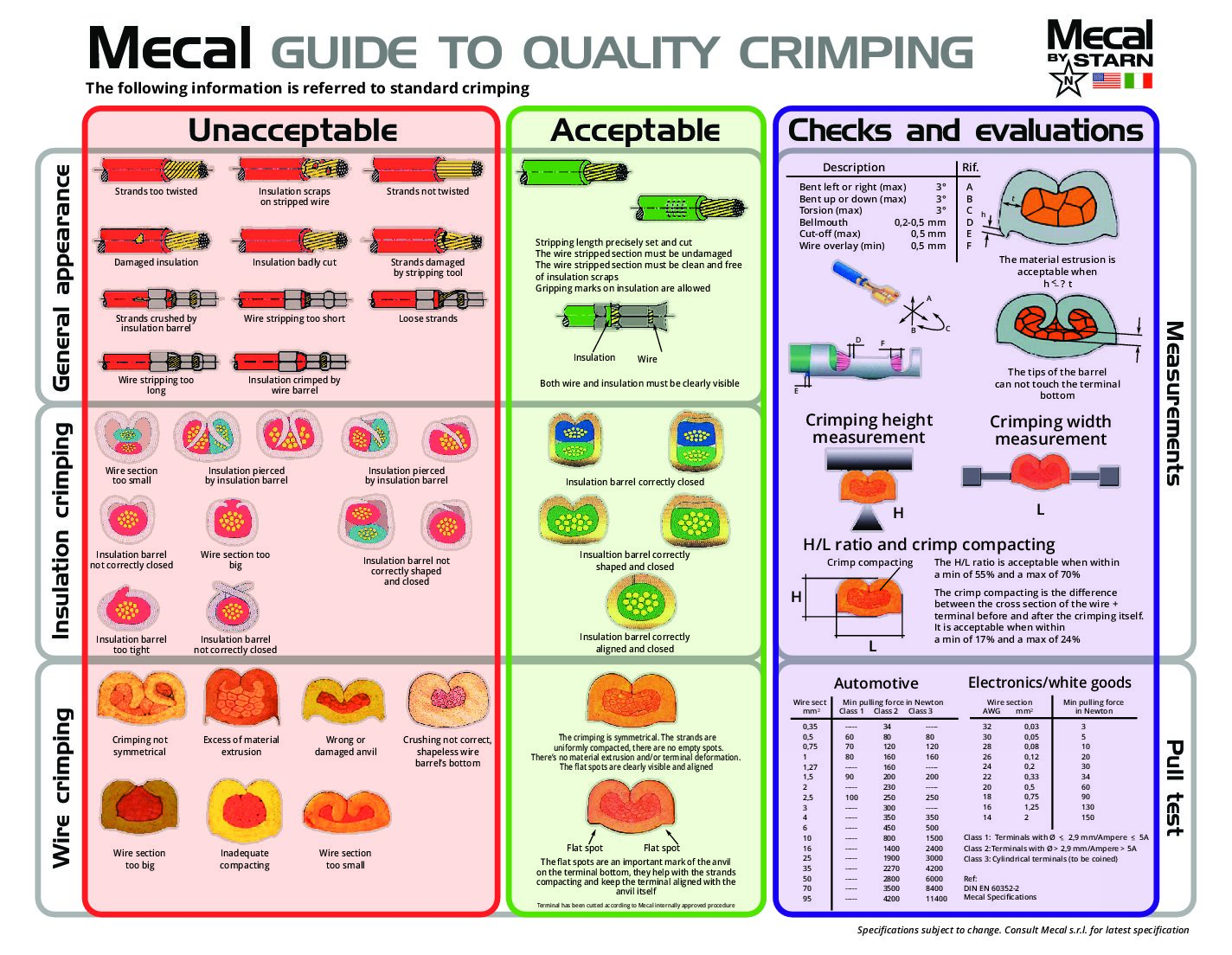

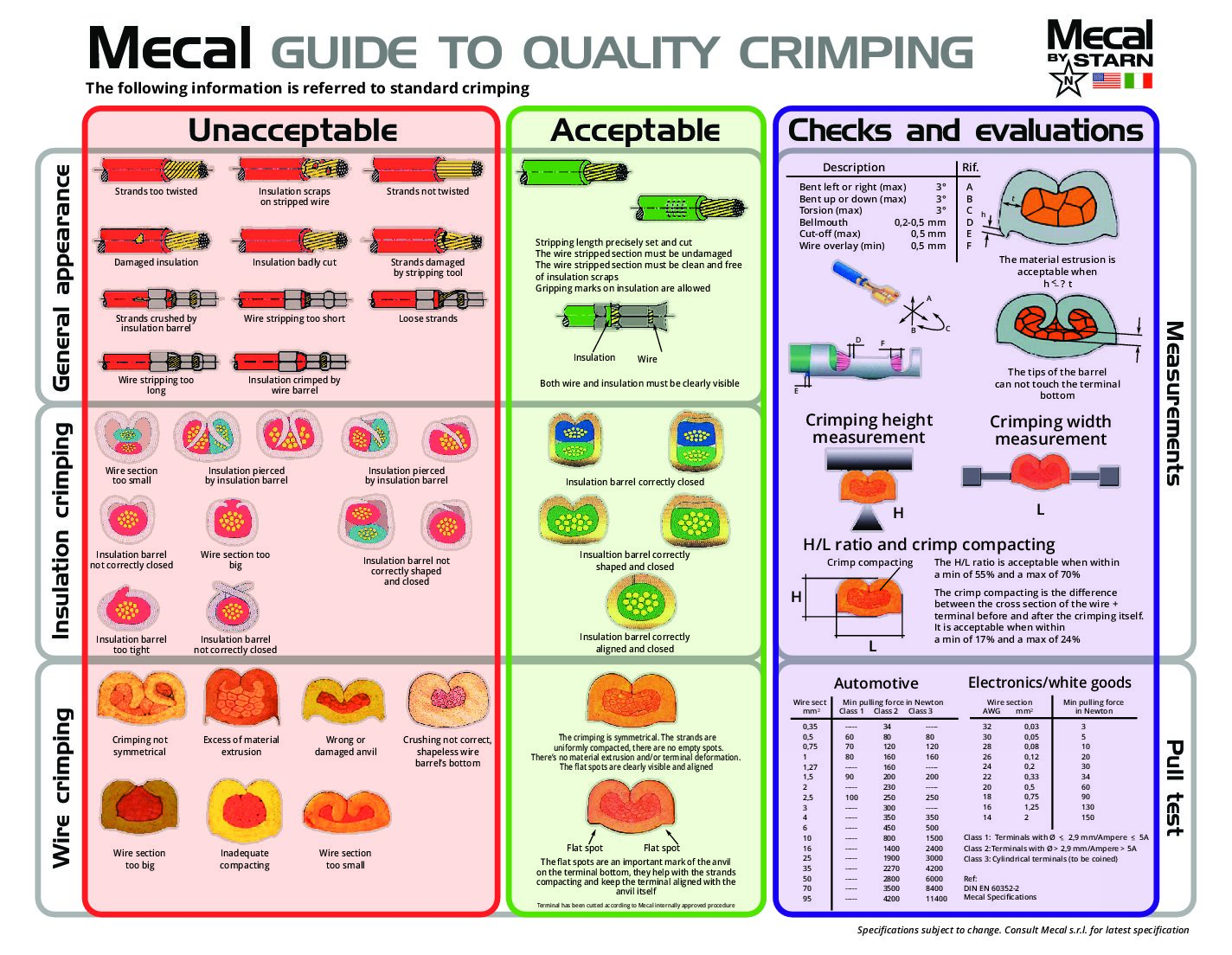

1) Core Crimp Height: Mecal crimp height specs dictate that acceptable height/width ratios should be between 55% and 70%.

The height/width ratio affects the compaction ratio (this is the difference between the cross-section of the wire and terminal before and after the crimp itself). This should be between 17% and 24%. The Crimp Height and Compaction Ratio will affect the pull test.

Crimp Height Adjustments can be made by the continuous regulating head.

2) Terminal Bend: Mecal crimp specs dictate that your terminal bend should be within 3 degrees left/right and up/down. Terminal bend that is out of spec may indicate other quality nonconformance issues such as centrality, bellmouth, and cut-off tab.

See our tutorial videos on how to make Terminal Bend Adjustments.

3) Burr: If you notice a burr while you're crimping you should immediately stop and inspect your crimp tools- this is an indicator of damaged crimp tools. If no damage is found, the burr must be less than or equal to the terminal thickness to be within specifications.

Burrs often cause issues when putting the terminated wire into housings.

4) Bellmouth: Bellmouths being out of tolerance can cause several problems- poor pull tests, shearing of wire strands, and improper fit into housings. Bellmouths should be at a minimum of .2mm and a maximum of .5mm.

1) Core Crimp Height: Mecal crimp height specs dictate that acceptable height/width ratios should be between 55% and 70%.

The height/width ratio affects the compaction ratio (this is the difference between the cross-section of the wire and terminal before and after the crimp itself). This should be between 17% and 24%. The Crimp Height and Compaction Ratio will affect the pull test.

Crimp Height Adjustments can be made by the continuous regulating head.

2) Terminal Bend: Mecal crimp specs dictate that your terminal bend should be within 3 degrees left/right and up/down. Terminal bend that is out of spec may indicate other quality nonconformance issues such as centrality, bellmouth, and cut-off tab.

See our tutorial videos on how to make Terminal Bend Adjustments.

3) Burr: If you notice a burr while you're crimping you should immediately stop and inspect your crimp tools- this is an indicator of damaged crimp tools. If no damage is found, the burr must be less than or equal to the terminal thickness to be within specifications.

Burrs often cause issues when putting the terminated wire into housings.

4) Bellmouth: Bellmouths being out of tolerance can cause several problems- poor pull tests, shearing of wire strands, and improper fit into housings. Bellmouths should be at a minimum of .2mm and a maximum of .5mm. MECAL BY STARN OFFERS

Presses ranging from 1.5 to 20 ton capabilities.

Mecal By Starn Sales

Mecal By Starn started as a partnership between Mecal and Starn Tool in order to supply North American Wire Harness Industry with world-class applicators, presses and spare parts from Mecal. Mecal was established in 1976 with the aim of supplying the wire harness industry with the best crimping equipment available. While Starn Tool, a well-respected precision machining company since 1945, has supported the wire harness industry since the 1960’s.

Today, Mecal by Starn is known for its customer service excellence across its expansive product line, as well as innovation and capability in custom-designed solutions to meet customer needs and help solve complex project challenges.

Mecal News

Meet Mauricio Valdebenito

Perishable Tooling & Reverse Engineering Solutions

A Better Option for your Production

WANT TO GET STARTED?

Talk to One of Our Experts